How Refrigeration Compressor Economizers Work

19-04-2022

The economizer is a heat exchanger that absorbs heat by throttling and evaporating the refrigerant itself so that another part of the refrigerant is supercooled.The economizer is often used in the refrigeration system of the secondary intake screw compressor. Under the condition that the evaporation temperature is relatively low (below -25°C), the efficiency of the ordinary single-stage screw compressor is reduced, the cooling capacity is reduced, and the exhaust gas is reduced. The temperature is higher, and the economizer air supply cycle can be used to improve the efficiency of the single-stage screw compression refrigeration cycle, increase the cooling capacity, and reduce the compressor discharge temperature. The use of economizers can make single-stage screw compressors more widely used and more economical.(1) The ammonia economizer is a flooded heat exchanger. A part of the ammonia liquid is throttled and evaporated outside the tube to enter the compressor air supply port, and the other part of the ammonia liquid is supercooled in the tube.

(2) The fluorine economizer is a dry heat exchanger. A part of the freon liquid is throttled and evaporated in the tube and then enters the air supply port of the compressor, and the other part of the freon liquid is supercooled outside the tube.Due to the characteristics of the compression process of the screw compressor (the volume of the compression chamber decreases and moves along the axial direction of the rotor), the suction phase can be completed and an additional suction port is formed where the gas pressure in the compression chamber increases slightly .Therefore, it is possible to input an additional gas flow rate without affecting the suction volume, ie an additional subcooling circuit can be added to the refrigeration system. Thus, the cooling capacity will be greatly increased due to the greater subcooling, while the input power increase due to the input plus mass flow will be small. The increase in system efficiency can be explained by the fact that additional compression work is generated from the higher suction pressure and therefore the system has a higher efficiency.

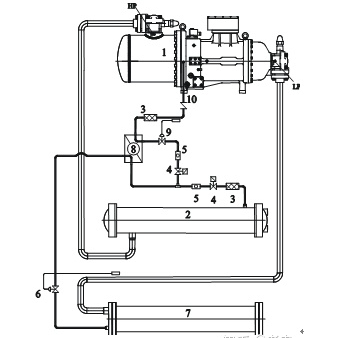

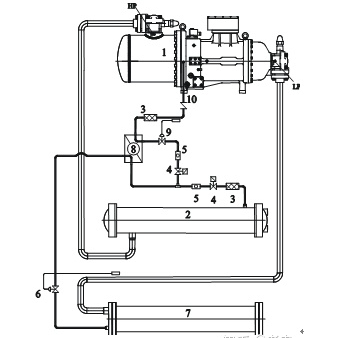

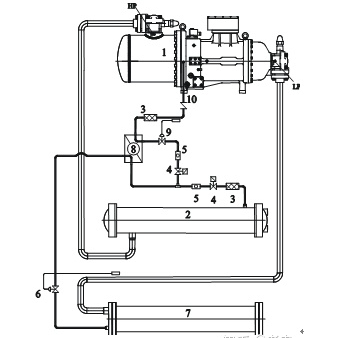

The economizer loop is shown in the diagram below. The heat exchanger exchanges heat with the refrigerant liquid with waste heat in the form of countercurrent, which is drawn from the liquid pipeline and expanded to the intermediate injection pressure through the expansion valve, and the liquid leaving the condenser is supercooled. The superheated vapor exits the heat exchanger and is injected into the economizer port to mix with the slightly compressed suction gas from the evaporator for further compression.

A two-stage expansion vessel under intermediate pressure can also be made.

Subcooler: Shell and tube, sleeve and plate heat exchangers can be used. The cooling capacity of the subcooler can be derived from the difference between the cooling capacity with and without the economizer. The subcooled liquid temperature must be at least 10 K higher than the intermediate pressure saturation temperature.Expansion valve: To prevent wet operation when the subcooler circuit is connected, it is recommended to use an expansion valve designed for liquid injection with a superheat setting of about 10 K.

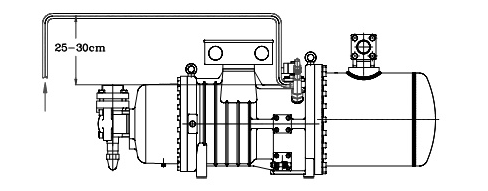

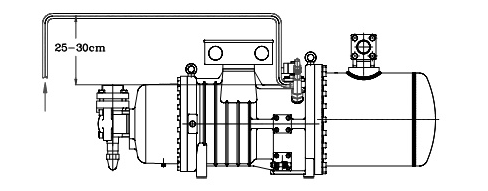

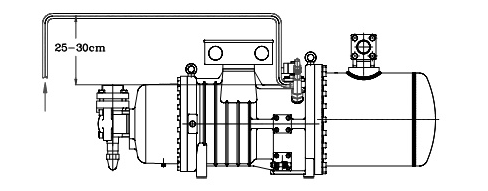

A refrigerant subcooler is suitably installed below the compressor to prevent backflow of oil or liquid from the compressor into the compressor during shutdown. In unstable operating conditions or when the subcooling circuit is turned off, the compressor will squeeze some oil out of the economizer injection port, so the liquid injection line should be bent into a curved section as shown in Figure 1. Since the economizer injection is directed to the rotor tooth profile, it is recommended to install a particularly fine filter (25um) on this line.

Due to the compression of the additional gas and the consequent overloading of the motor, the operating range of the economizer will be partially limited at high temperatures.

For high condensing temperatures, the motor should be enlarged.

Notice! The subcooling circuit can only be used when the compressor is at full load.

During the start-up phase (low load conditions), the subcooling circuit should be closed until the operating conditions stabilize. (It is recommended to use a delay relay to connect the economizer circuit).

Get the latest price? We'll respond as soon as possible(within 12 hours)